Abstract

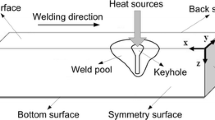

A 2-D numerical model was developed to predict the shape of weld pool in stationary GTA welding of commercial pure aluminium, without considering fluid flow in the weld pool. A Gaussian current density and heat input distribution on the surface of the workpiece were considered. The parameters of Gaussian distribution were modified by comparing calculated results with experimental ones. It was found that these distribution parameters are functions of applied current and arc length. Effects of arc length, applied current and welding time on the geometry of the weld pool were investigated. To check the validity of the model, a series of experiments were also conducted. In general, the agreement between calculated overall shape of the weld pool and the experimental one was acceptable, especially in low applied currents. Therefore, it can be concluded that in pure aluminium, the heat conduction is dominant mechanism of heat transfer in the weld pool.

Similar content being viewed by others

References

ZACHARIA T, DAVID S A, VITEK J M, KRAUS H G. Computational modeling of stationary gas-tungsten-arc weld pools and comparison to stainless steel 304 experimental results [J]. Metallurgical Transactions B, 1991, 22B: 243–257.

JOU M. Experimental study and modeling of GTA welding process [J]. J Manuf Sci Eng, 2003, 125: 801–808.

AIDUN D K, DOMEY J J, AHMADI G. Digital simulation of a stationary and a linear weld. Metall [J]. Mater Trans B, 2002, 33B: 101–110.

WU C S, YAN F. Numerical simulation of transient development and diminution of weld pool in gas tungsten arc welding [J]. Modelling Simul Mater Sci Eng, 2004, 12: 13–20.

TANAKA M, TERASAKI H, USHIO M, LOWKE J J. A unified numerical modeling of stationary tungsten-inert-gas welding process [J]. Metall Mater Trans A, 2002, 33A: 2043–2052.

FARZADI A, SERAJZADEH S, KOKABI A H. Modeling of heat transfer and fluid flow during gas tungsten arc welding of commercial pure aluminum [J]. Int J Adv Manuf Technol, 2008, 38: 258–267.

KIM I S, BASU A. A mathematical model of heat transfer and fluid flow in the gas metal arc welding process [J]. J Mate Process Tech, 1998, 77: 17–24.

MARAN P, SORNAKUMAR T, SUNDARARAJAN T. Modeling of linear gas tungsten arc welding of stainless steel [J]. Metall Mater Trans B, 2008, 39B: 619–628.

LU F, TANG X, YU H, YAO S. Numerical simulation on interaction between TIG welding arc and weld pool [J]. Comp Mate Sci, 2006, 35: 458–465.

GOODARZI M, CHOO R, TOGURI J M. The effect of the cathode tip angle on the gas tungsten arc welding arc and weld pool: II. The mathematical model for the weld pool [J]. J Phys D: Appl Phys, 1998, 31: 569–583.

KIM W H, FAN H G, NA S J. A mathematical model of gas tungsten arc welding considering the cathode and the free surface of the weld pool [J]. Metall Mater Trans B, 1997, 28B: 679–686.

BISEN K B, ARENAS M, EL KADDAH N, ACOFF V L. Computation and validation of weld pool dimensions and temperature profiles for gamma TiAl [J]. Metall Mater Trans A, 2004, 34A: 2273–2279.

TSAI N S, EAGAR T W. Distribution of the heat and current fluxes in gas tungsten arc [J]. Metallurgical Transactions B, 1985, 16B: 841–846.

LU F, YAO S, LOU S, LI Y. Modeling and finite element analysis on GTAW arc and weld pool’ [J]. Comp Mater Sci, 2004, 29: 371–378.

DONG W, LU S, LI D, LI Y. GTAW liquid pool convections and the weld shape variations under helium gas shielding [J]. International Journal of Heat and Mass Transfer, 2011, 54: 1420–1431.

FARZADI A, SERAJZADEH S, KOKABI A H. Investigation of weld pool in aluminum alloys: Geometry and solidification microstructure [J]. International Journal of Thermal Sciences, 2010, 49: 809–819.

DONG W, LU S, LI D, LI Y. Modeling of the weld shape development during the autogenous welding process by coupling welding arc with weld pool [J]. Journal of Materials Engineering and Performance, 2010, 19: 942–950.

JAMSHIDI H, FARZADI A, SERAJZADEH S, KOKABI A H. Theoretical and experimental study of microstructures and weld pool geometry during GTAW of 304 stainless steel [J]. Int J Adv. Manuf Technol, 2009, 42: 1043–1051.

SHABANI M O, MAZAHERY A, BAHMANI A, DAVAMI AND P, VARAHRAM N. Solidification of A356 Al alloy: Experimental study and modeling [J]. Metalic Materials, 2011, 49: 253–264.

AHMAD BAHMANI, NADER HATAMI, NASER VARAHRAM, PARVIZ DAVAMI, MOHSEN OSTAD SHABANI. A mathematical model for prediction of microporosity in aluminum alloy A356 [J]. Int J Adv Manuf Technol, 2012, 64(9/10/11/12): 1313–1321.

PEHLKE R D. Summary of thermal properties for casting alloys and mold materials [M]. 1st ed. US: University of Michigan, 1982: 81–94.

HATCH J E. Aluminum: Properties and physical metallurgy [M]. US: American Society for Metals / Metals Park, 1984: 4–16.

HOLMAN J P. Heat transfer [M]. 9th ed. New York: Mc-Graw Hill, 2001: 330–331.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Faraji, A.H., Bahmani, A., Goodarzi, M. et al. Numerical and experimental investigations of weld pool geometry in GTA welding of pure aluminum. J. Cent. South Univ. 21, 20–26 (2014). https://doi.org/10.1007/s11771-014-1910-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-014-1910-y